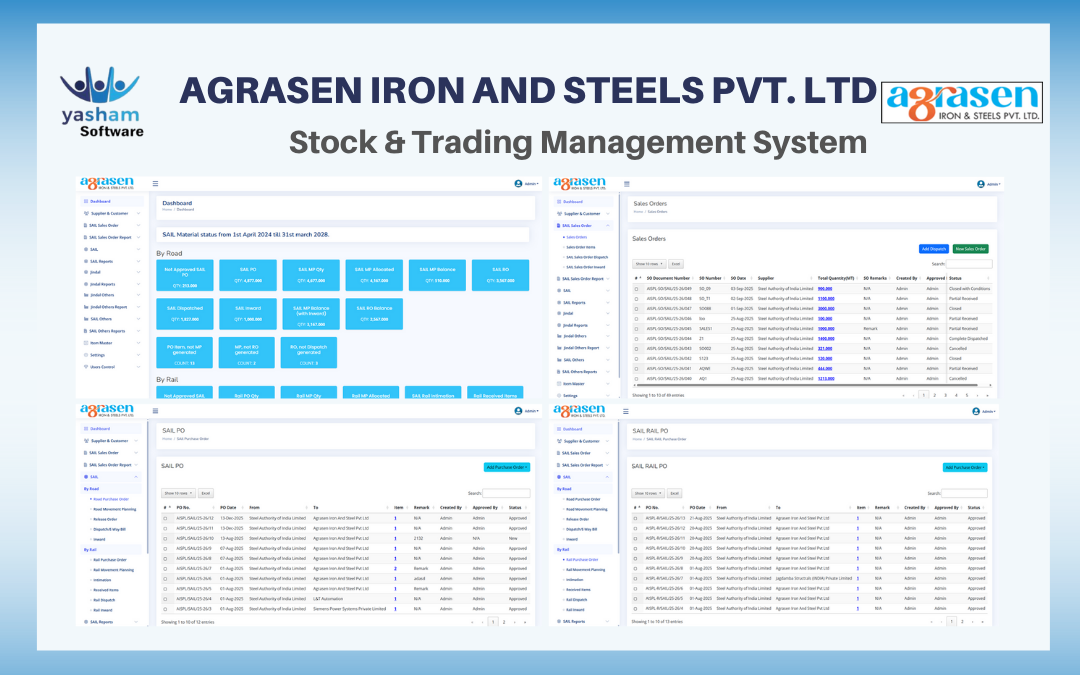

Client Overview

Client Name: Agrasen Iron and Steels Pvt. Ltd.

Established: 2010

Industry: Structural Steel Trading & Distribution

Location: India

Agrasen Iron and Steels Pvt. Ltd. is a large-scale structural steel trading

company serving engineering and infrastructure projects across India.

The organization is an MOU customer of SAIL, a stocking partner of

JSPL (Jindal Steel & Power Ltd.) and

RINL (Rashtriya Ispat Nigam Ltd.), with an audited annual turnover

exceeding ₹230+ Crores.

Project Objective

The objective of this project was to build a

custom Stock Management System / ERP solution that could:

- Centralize tracking of SAIL, Jindal, and RINL orders

- Provide real-time visibility into MP, RO, Dispatch, and Inward movements

- Eliminate spreadsheet dependency

- Enable role-based access for multi-department operations

- Improve reporting accuracy and decision-making speed

Challenges

Before implementing the system, Agrasen faced several challenges:

- Manual tracking of SAIL & Jindal orders, dispatch, and inward status

- No centralized visibility across financial years for material movement

- Heavy reliance on spreadsheets for MP / RO / Dispatch planning

- Difficulty generating real-time reports and supplier performance analysis

- No structured role-based access for operations, sales, accounts, and warehouse teams

Our Approach

Platform & System Design

We designed and developed a

cloud-based custom ERP & Stock Management System,

tailored specifically for Agrasen’s high-volume steel trading operations.

Our approach focused on:

- End-to-end material traceability

- Real-time dashboards and analytics

- Secure role-based access control

- Modular architecture for scalability

- Centralized reporting for management

System Structure

The system was structured into integrated modules for operational clarity:

- Supplier & Customer Management

- Order Tracking

- Purchase Order Management

- Movement Planning

- Release Order (RO) Management

- Dispatch & E-Way Bill Management

- Inward Entry

- Item Master & Reporting

- Role-based User Access

- Cloud-based Platform Infrastructure

Each module works seamlessly to ensure data accuracy and transparency.

Key Features Delivered

- Supplier & Customer Management: Centralized partner data

- Order Tracking: Live tracking of orders across all stages

- Purchase Orders: Structured procurement management

- Movement Planning: MP planning with execution visibility

- Release Orders: RO tracking and status management

- Dispatch & E-Way Bills: Integrated dispatch documentation

- Inward Entry: Real-time inward stock updates

- Item Master: Standardized product configuration

- Reporting: Detailed operational and performance reports

- Role-based Access: Secure workflows for different departments

- Cloud Platform: Anywhere access with real-time updates

Benefits & Results

- Improved traceability of material flow from MP to Dispatch & Inward

- Significant reduction in manual work and spreadsheet dependency

- Faster and more accurate report generation for management

- Clear visibility into stock, supplier-wise performance, and delivery status

- Improved internal security and workflow control through role-based access

- Faster decision-making supported by real-time dashboards

Conclusion

The Stock Management System successfully transformed Agrasen Iron and Steels

Pvt. Ltd.’s complex and spreadsheet-driven operations into a

centralized, cloud-based digital platform.

By enabling real-time tracking, structured workflows, and accurate reporting,

the solution enhanced efficiency, transparency, and control—positioning

Agrasen for scalable growth and long-term operational excellence.