Client Overview

Client Name: RYB Industries

Established: 2000

Industry: Engineering & Manufacturing

Location: India

RYB Industries is an established engineering and manufacturing company delivering

industry-compliant electrical solutions. Their core product range includes AC/DC

Power Distribution Panels, Power Bus Ducts, DOL & Star-Delta Starter Control Panels,

Lighting Distribution Boards, and other industrial electrical systems supporting

infrastructure and automation projects.

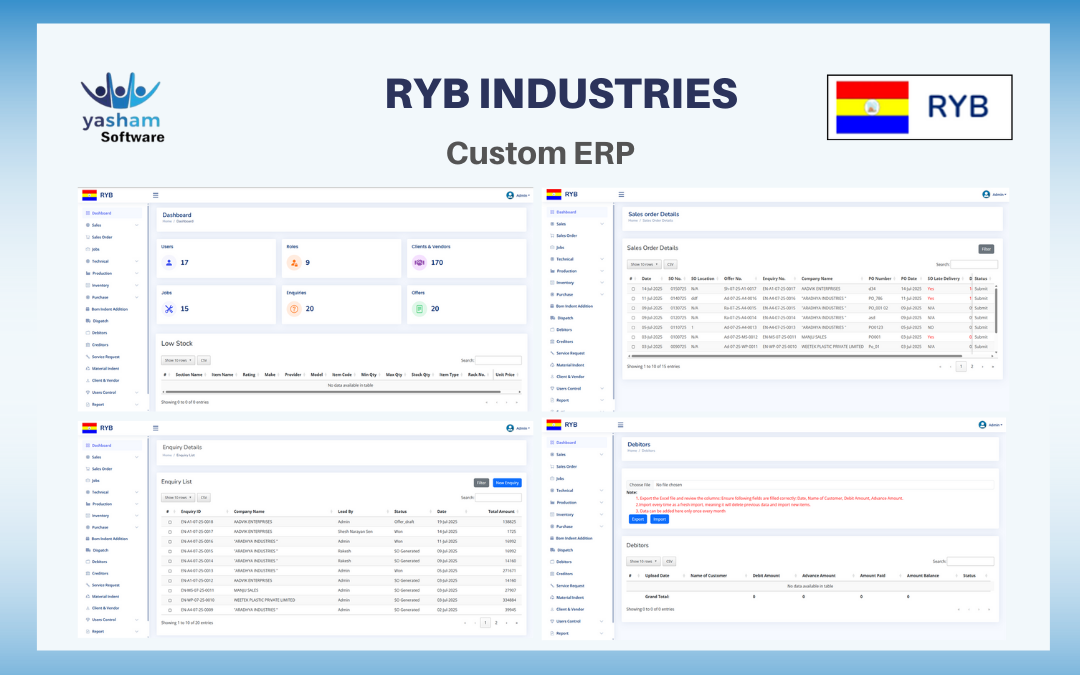

Project Objective

The objective of this project was to design and implement a

Custom ERP & Inventory Management System that could:

- Replace manual and spreadsheet-driven workflows

- Centralize enquiries, orders, jobs, inventory, and service data

- Enable real-time tracking of stock, dispatches, and operations

- Improve coordination between sales, technical, purchase, and service teams

- Build a scalable digital platform for future expansion

Challenges

Before implementing the ERP system, RYB Industries faced several operational challenges:

- Manual workflows across departments causing inefficiencies and slow response times

- No centralized system to track enquiries, orders, jobs, or client/vendor information

- Difficulty monitoring stock levels and managing dispatches in real time

- Lack of a digital system for service requests, documentation, and production tracking

- Heavy reliance on spreadsheets, increasing the risk of errors and data duplication

Our Approach

Platform & System Design

We designed and developed a custom ERP solution specifically tailored

to RYB Industries’ engineering and manufacturing workflows.

Our approach focused on:

- Modular ERP architecture for flexibility and scalability

- Centralized data flow across sales, jobs, inventory, and service operations

- Real-time dashboards for leadership and operational teams

- Role-based access for enhanced security and accountability

- Future-ready design supporting mobile access and advanced analytics

ERP System Structure

The system was structured into clearly defined modules to ensure seamless operations:

- Sales & Enquiries

- Jobs & Technical Coordination

- Inventory Management

- Purchase & Dispatch

- Client & Vendor Management

- Service Request Handling

- Real-time Dashboard

- Data Migration & Consolidation

Each module operates independently while remaining fully integrated within the ERP ecosystem.

Key Features Delivered

- Sales & Enquiries: Centralized tracking of enquiries, offers, and orders

- Jobs & Technical Coordination: Smooth collaboration between engineering and production teams

- Inventory Management: Real-time stock visibility with low-stock alerts

- Purchase & Dispatch: Streamlined procurement and dispatch tracking

- Client & Vendor Management: Consolidated records and transaction history

- Service Request Handling: Digital service and documentation management

- Real-time Dashboard: Live operational KPIs and workflow status

- Data Migration & Consolidation: Unified historical data visibility

Benefits & Results

- Significant improvement in inter-department coordination

- Reduction in manual errors and data duplication by up to 70%

- Improved visibility into enquiries, inventory, and dispatch timelines

- Better inventory and vendor management with timely alerts

- Faster decision-making through real-time operational insights

- Scalable ERP platform ready for future digital expansion

Conclusion

The Custom ERP & Inventory Management System transformed RYB Industries’ operations

by replacing fragmented manual workflows with a centralized, real-time digital platform.

The solution enhanced efficiency, transparency, and control across departments while

positioning the organization for scalable growth and long-term digital transformation.