Client Overview

Client Name: Jalan Steel Industries

Industry: Steel Wholesale & Trading

Established: 2001

Location: India

Jalan Steel Industries is a well-established wholesaler and trader dealing in a wide

range of mild steel products. Their portfolio includes Mild Steel Angle, Channel, Pipe,

Plate, Bar, Sheet, and TMT Steel Bars. The business operates at high transaction volumes,

requiring accurate stock control and efficient order management.

Project Objective

The objective of this project was to develop a

Stock Tracking System integrated within a custom ERP solution to:

- Centralize stock, sales, and purchase data

- Improve visibility into open orders and inventory levels

- Reduce dependency on spreadsheets

- Enable real-time tracking of stock movement and pending bills

- Support scalable growth with accurate reporting and dashboards

Challenges

Before implementing the system, the client faced several operational challenges:

- Manual handling of high volumes of sales and purchase transactions

- Lack of visibility into open sales orders, purchase orders, and pending bills

- Difficulty tracking low-stock items, leading to fulfillment delays

- Limited reporting for pricing, stock movement, and transaction history

- Heavy reliance on spreadsheets, increasing the risk of errors

Our Approach

Platform & System Design

We designed and implemented a custom Stock Management System

as part of a tailored ERP solution for Jalan Steel Industries.

Key focus areas included:

- Real-time stock visibility across all transactions

- Structured workflows for inward and outward stock movement

- Simple pricing and item categorization management

- User-friendly dashboards for quick decision-making

- Scalable architecture to support future business growth

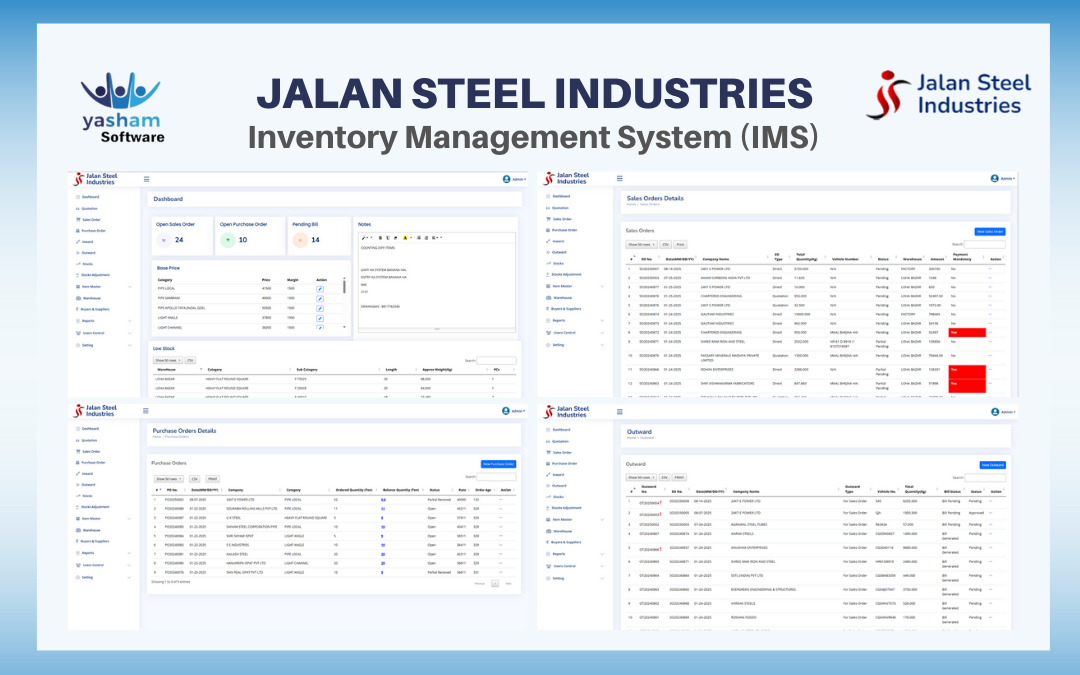

System Structure

The Stock Tracking System was organized into well-defined modules for operational clarity:

- Stock Management

- Inward & Outward Tracking

- Purchase Order Management

- Sales Order Management

- Item Master

- Reports & Analytics

- Real-time Dashboard

- Order Fulfillment & Invoicing

Each module is tightly integrated to ensure data accuracy and seamless information flow

across the system.

Key Features Delivered

- Stock Management: Real-time tracking of stock availability and movement

- Inward / Outward Tracking: Accurate recording of material inflow and outflow

- Purchase Orders: Streamlined procurement and vendor tracking

- Sales Orders: End-to-end sales order processing

- Item Master: Centralized control of pricing, categories, and margins

- Reports: Detailed insights into stock, pricing, and transactions

- Real-time Dashboard: Live view of open orders, pending bills, and low stock

- Order Fulfillment: Seamless linkage between inventory, invoicing, and dispatch

Benefits & Results

- Improved visibility and control over inventory levels

- Reduced stock discrepancies and manual errors

- Simplified pricing management with faster updates

- Real-time tracking of pending bills and low-stock items

- Faster and more informed business decisions

- Reduced paperwork through automated workflows

- Scalable system supporting business expansion

Conclusion

The Stock Tracking System transformed Jalan Steel Industries’ inventory and order

management processes. By replacing spreadsheet-based workflows with a centralized,

real-time ERP solution, the system improved accuracy, efficiency, and operational

transparency—positioning the business for scalable growth and long-term success.